What is the Strongest Best 3D Printer Filament? A Guide to the Most Durable Filaments

Introduction

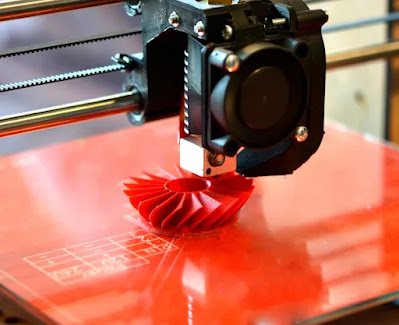

3D printer has revolutionized how we create objects, from everyday items to complex parts used in industries like aerospace and automotive. One crucial aspect of 3D printing is the type of filament used, which can significantly impact the strength and durability of the printed part. In this article, we will explore the strongest 3D printer filaments and guide you in choosing the most durable filament for your printing needs.

Top 3 Strongest 3D Printer Filaments

Carbon Fiber Filament

Carbon fiber filament is one of the strongest filaments available in the market. It is reinforced with carbon fiber, making it incredibly strong and durable. Carbon fiber filament is widely used in automotive, aerospace, and sports equipment due to its exceptional properties.

One of the primary advantages of carbon fiber filament is its lightweight and high stiffness. The high stiffness of the filament makes it ideal for parts that require rigidity and stability. Moreover, carbon fiber filament has excellent tensile strength, which means it can withstand significant pulling force before breaking. The high tensile strength makes it an excellent option for creating parts that must endure high stress or strain, such as drone frames or racing car components.

However, carbon fiber filament also has some disadvantages that must be considered. Firstly, the filament is relatively expensive compared to other filaments. Additionally, it can be challenging to print due to its high stiffness, resulting in warping and poor bed adhesion. To overcome this, it's recommended to use a heated bed and an enclosure to maintain a consistent temperature during printing.

Nylon Filament

Nylon filament is another durable option known for its high strength, flexibility, and impact resistance. It is an excellent choice for creating parts that must withstand wear and tear and can be used in industrial applications due to its high chemical resistance.

Nylon filament is also known for its excellent layer adhesion, which results in strong and durable parts. Its high tensile strength makes it an excellent option for creating parts that need to endure bending and stretching, such as gears or hinges.

One of the primary advantages of nylon filament is its flexibility, which allows it to bend and deform without breaking. Additionally, it can be dyed to a wide range of colors, making it an excellent option for creating vibrant and colorful objects.

However, nylon filament also has some disadvantages that need to be considered. Firstly, it can be challenging to print due to its high flexibility, resulting in warping and poor bed adhesion. Using a heated bed and an enclosure is recommended to maintain a consistent temperature during printing.

Additionally, nylon filament is susceptible to moisture absorption, resulting in poor print quality and adhesion. Therefore, it's essential to store the filament in a dry environment.

Polycarbonate Filament

Polycarbonate filament is extremely strong and durable, making it ideal for printing tough and impact-resistant parts. It has excellent temperature resistance and can withstand high temperatures without deforming or breaking.

One of the primary advantages of polycarbonate filament is its high impact resistance. It can withstand significant force before breaking, making it an excellent option for creating parts that need to endure impacts, such as phone cases or helmet components. Polycarbonate filament has excellent chemical resistance, making it ideal for creating parts used in harsh chemical environments.

However, polycarbonate filament also has some disadvantages that need to be considered. Firstly, it can be challenging to print due to its high melting point, which requires a heated bed and an enclosure to maintain a consistent temperature during printing. Additionally, polycarbonate filament is prone to warping and cracking, which can result in poor print quality.

Factors to Consider When Choosing a Filament

When choosing a filament for your 3D printing needs, several factors should be considered to ensure the printed part is strong and durable. Some of the critical factors include:

Strength Requirements: The first factor to consider when choosing a filament is the strength requirements of the printed part. If the part needs to withstand high stress or strain, choosing a filament with high tensile strength, such as carbon fiber filament, is essential.

Application: The application of the printed part also determines the filament to be used. If the part will be used in harsh chemical environments, it's recommended to use a filament with high chemical resistance, such as polycarbonate.

Printing Parameters:

The printing parameters, such as temperature, speed, and layer height, also play a crucial role in determining the strength and durability of the printed part. Choosing a filament compatible with your 3D printer and can be printed using the recommended settings is essential.

Post-processing:

Post-processing techniques, such as sanding, polishing, or coating, can significantly improve the strength and durability of the printed part. Therefore, it's essential to consider the post-processing techniques used when choosing a filament.

Cost:

The cost of the filament is also an essential factor to consider. Some filaments, such as carbon fiber filament, are relatively expensive compared to others. Therefore, it's essential to consider the cost when choosing a filament, especially for large or complex parts.

Conclusion

In conclusion, choosing the right filament for your 3D printing needs is crucial to ensure that the printed part is strong and durable. Carbon fiber, nylon, and polycarbonate are some of the strongest filaments available in the market, each with unique properties and advantages. When choosing a filament, it's essential to consider factors such as strength requirements, application, printing parameters, post-processing, and cost. Considering these factors, you can select the most durable filament for your printing needs and create high-quality parts that meet your requirements.

Comments

Post a Comment